Pallet packing is an occupation that requires stamina, accuracy and adaptability to monotonous and repetitive activities. Therefore, it is a bad job for humans. But it's a perfect choice for a machine that doesn't get tired or sick, always has good stamina, can work in low and high temperatures, and doesn't require vacation, pay or insurance. If you typically pack 60 pallets per month, you'd better save yourself and buy a manual dispenser. If packing 60 pallets is a day's work for you, then a pallet stretch wrapper may be the right choice.

Experts say we've just witnessed the fourth industrial revolution. It started with the development of the Internet and is now evolving with rapid automation and robotics. The role of humans in Industry 4.0 will be limited to supervising and controlling machines.

Even now, you can purchase a fully automated line that not only packs pallets, but also automates the stacking, packing, palletizing and storage of goods. Due to the high cost, this solution is only suitable for large freight, trading and production companies. However, for most companies, semi-automatic stretch wrapping machines that may result in quite significant savings are possible.

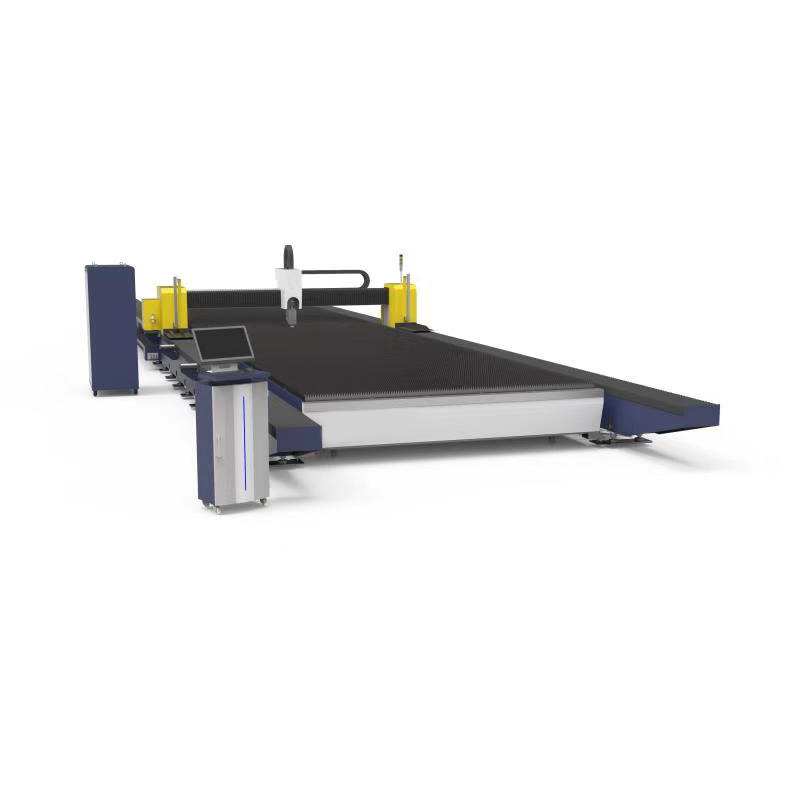

X100 Fully Automatic Pallet Wrapping Machine

Rotary turntables, rotary arms and robots

Two main technological solutions are used in pallet wrapping machines. In the first type, the tray remains stationary while an arm with a film dispenser rotates around the load, which starts at the bottom of the load and gradually wraps it to the top.

The other solution is the rotating turntable (platform): the pallet rotates around its own axis while the film dispenser moves up from the bottom along a fixed column.

A third solution is the robot, a self-propelled wrapper with a movable dispenser. The machine moves to the selected pallet and wraps it with film.

Optimal film tension and cost

Regardless of the technological solution applied in the wrapping machine, the goal of its use is to optimize the entire wrapping process. This can be achieved in the following areas.

Featured content:Gate Conveyor: Streamlining Material Handling ProcessesEnhancing Safety and Quality Control: The Importance of Glove Leak Detection MachinesThe Benefits of Using a Dog Food MachineWhat are the benefits of using a hydraulic mill roll stand?Vane Compressors: The Workhorses of Efficient Air CompressionWhat Are the Advantages of Forklifts?Advantages of Electric Wheel LoadersReducing labor costs

Tray wrapping machines can reduce labor costs, as working hours are reduced and machines replace manual labor.

Reduction of consumables

the precise application of film and the possibility of using pre-stretched film can save film and thus reduce consumables.

Horizontal Fully Automatic Pallet Stretch Wrapping Machine

Improved packaging quality

Pallet wrapping machines are more precise than humans - not only can they apply properly stretched film more evenly and precisely, but they are often faster.

Even if packaging costs are in the thousands or tens of thousands of zlotys, automation leads to cost optimization in the long run.

That said, remember that any form of packaging automation should precede precise pallet preparation. Pallet preparation is the optimal arrangement and packaging of goods on pallets based on the results of packaging planning algorithms. Therefore, while investing in a packaging machine, it is worthwhile to apply both packaging and package alignment automation of goods on pallets based on special algorithms.

If you need any help, please contact us today to get your solutions.

Featured content:The Laser Cutter Revolution: Transforming Design and ManufacturingThe Working Principle of the Vacuum Tube Furnace and Precautions.Benefits of Using CNC Rolling Machines for Sheet Metal FabricationIntroduction to Wheat Flour Milling Plant: A Comprehensive GuideLine Pipe vs. OCTG: Understanding the Differences in Oil and Gas IndustryExploring the Distinctions Between Diesel and Petrol ForkliftsShrimp Pouring Machine: Revolutionizing Seafood Processing

Comments

Please Join Us to post.

0