Coil feed lines are crucial components in the metal forming industry, as they transport metal coils through various processes, including cutting, punching, and stamping.

Coil feed lines are crucial components in the metal forming industry, as they transport metal coils through various processes, including cutting, punching, and stamping. Proper maintenance of the coil feed line can help prevent downtime, reduce costs, and extend the life of the equipment. In this article, we will provide some tips for proper coil feed line maintenance.

Keep the Equipment Clean and Lubricated

One of the most basic maintenance tasks for a coil feed line is to keep the equipment clean and lubricated. Dirt, debris, and metal shavings can accumulate on the equipment over time, causing wear and tear on the moving parts. Cleaning the equipment on a regular basis can help prevent this build-up and ensure that the equipment continues to operate smoothly.

Additionally, lubricating the moving parts of the coil feed line can reduce friction and wear. The manufacturer's manual will provide recommendations for the type of lubricant to use and the frequency of lubrication. It is important to follow these recommendations to ensure the proper functioning of the equipment.

Check the Feed Line for Wear and Damage

Over time, the coil feed line can experience wear and damage, which can affect its performance. Regular inspections can help identify these issues before they cause significant problems. It is recommended to check the feed line for wear and damage after every shift, or at least once a day.

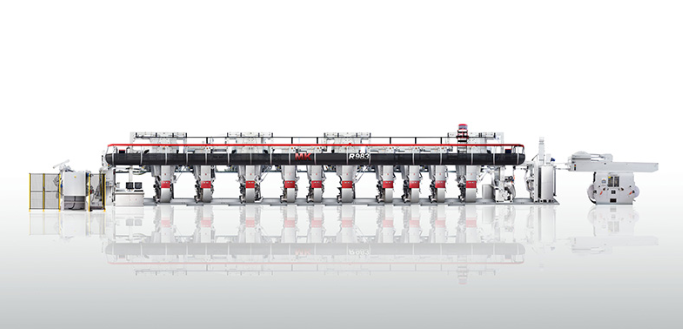

Coil Blanking Line

Some common signs of wear and damage to look for include:

Bent or cracked rollers

Worn or damaged feed guides

Damaged or worn pinch rolls

Loose or damaged fasteners

Worn or damaged gears

If any of these issues are identified, it is important to address them promptly to prevent further damage and downtime.

Maintain Proper Tension

Proper tension is critical for the successful operation of the coil feed line. If the tension is too loose, the coil may slip or feed inconsistently, leading to quality issues and downtime. If the tension is too tight, the coil may stretch or break, again causing quality issues and downtime.

The manufacturer's manual will provide recommendations for the proper tension based on the type and thickness of the material being fed. It is important to follow these recommendations and to regularly check the tension to ensure that it remains within the proper range.

Featured content:How Does an Induction Brazing Machine Work?What is Common Blow Molding Problems and Solutions?The Advantages of Plasma Cutting in Metal FabricationTriple Offset Butterfly Valve Manufacturer: Enhancing Industrial Flow ControlWhat Are The Benefits of Using Induction Pipe Bending Machine?What factors should I consider when choosing the unpowered beading machine for my crafting needs?What is a pouch packaging machine used for?Check and Adjust the Straightener

The straightener is a critical component of the coil feed line, as it ensures that the material being fed is flat and straight. Regular inspections can help identify issues with the straightener and allow for adjustments to be made before they become significant problems.

Some common issues with the straightener include:

Worn or damaged rollers

Misaligned rollers

Incorrect roller pressure

Bent or damaged frame

If any of these issues are identified, it is important to address them promptly to prevent further damage and downtime.

Maintain Proper Alignment

Proper alignment is critical for the successful operation of the coil feed line. Misalignment can cause the material to feed inconsistently, leading to quality issues and downtime. Regular inspections can help identify alignment issues and allow for adjustments to be made before they become significant problems.

Some common causes of misalignment include:

Loose or damaged fasteners

Worn or damaged rollers

Misaligned or worn feed guides

Misaligned or worn pinch rolls

It is important to check the alignment of the coil feed line regularly and make any necessary adjustments to ensure that the material feeds properly.

Contact us to find a coil feed line that’s right for your business.

source

Featured content:What are Metal Shredders and How Do They Work?Do you know the advantages of lintel making machineWhat is the advantage of telescopic boom lift?How long does ozone treatment for car take?What does a bucking unit do?What are AC/DC TIG Welding Machines, and What Makes Them So Great?What is the Difference Between a Condenser and a Cooling Tower?

Comments

Please Join Us to post.

0