The Variable Speed Driver,usually short for VSD, is the hallmark of the compressed air field. Air compressors equipped with VSD are able to automatically adjust their operating speed to precisely match compressed air demand in real time. This is especially important when it comes to saving energy, considering that the biggest cost is the electricity it consumes, not the purchase price of the air compressor itself!

On average, energy saving for VSD compressor is 35% to 50%, depending on the size and type of application. Turn that percentage into an expense, and you can save a lot of money.

What is the difference between a fixed speed compressor and an variable speed compressor?

Let's first understand some of the differences between fixed speed compressors and inverter compressors. Fixed speed compressors are generally simple machines with low upfront costs. It's not a complicated concept to turn on a line frequency compressor and let it run at full speed until it needs to be turned off.

Inverter compressors are not built to run continuously at full speed, they do more than just run and stop, instead they precisely match output to demand, making them more precise than fixed speed compressors, which means these The initial investment in the machine can increase significantly.

When Should Inverter Compressors Be Considered?

While inverter technology sounds ideal for any business, it's not always the right solution for every one! Inverter compressors are ideal for businesses with fluctuating demand; facilities running different processes may be considered. Specific situations that may require an inverter compressor include:

>There are significant differences in the demand for compressed air in the quality inspection of different jobs;

>Demand fluctuates with shifts, weekdays (i.e. weekends), or seasonality; or production requires tight pressure bands;

If the process is consistent in operation and does not experience demand fluctuations, or if these changes are not large, then the use of a line frequency compressor may be an appropriate option.

Also consider a solution that combines a line compressor and an inverter compressor, with the line compressor providing the base load and one or more inverter compressors "fine-tuning" to meet changes in demand.

What are the benefits of an inverter compressor?

> Although inverter compressors have a higher initial investment cost, they repay the increased investment through energy savings, and the greater the change in demand, the greater the potential energy savings.

> The working pressure range of the inverter compressor is much narrower than that of the fixed speed compressor. They work at lower delivery pressures, the minimum working pressure required to maintain the air system. They also provide more stable discharge pressure for all compressed air applications throughout the facility.

> The net pressure of the inverter compressor can be set lower than the no-load pressure of the power frequency compressor.

> The inverter compressor can be started/stopped at full system pressure without unloading, which saves time and effort, and there is no idling time loss, and no emissions loss that occurs during normal operation.

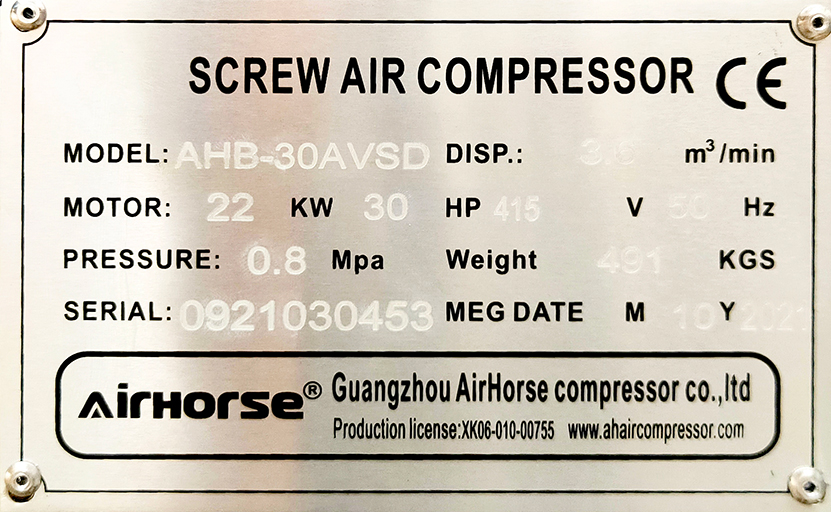

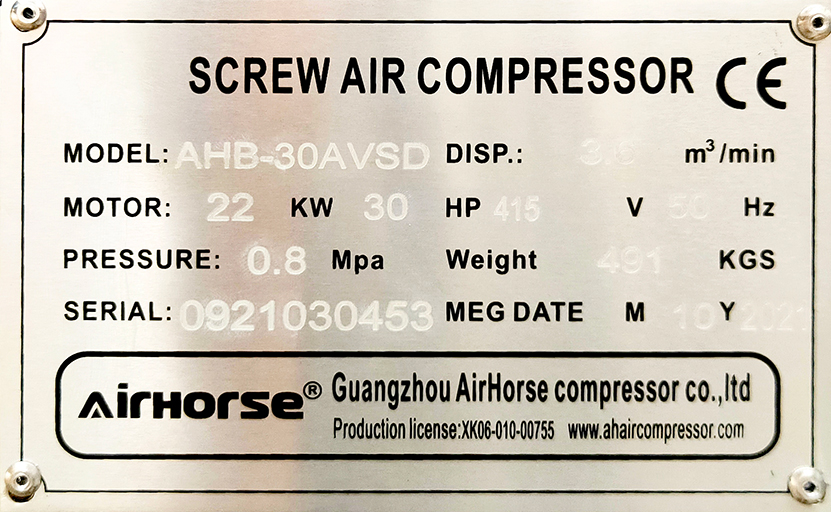

Guangzhou AirHorse Compressor co., ltd. is committed to providing air compression energy-saving solutions for global industrial users. After more than 20 years of industry accumulation, it has passed ISO9001, quality system certification, ISO14001 environmental quality system certification, and has CE and UL certification. Product sales to more than 130 countries and regions around the world.

Comments

Please Join Us to post.

0