How does spark plasma sintering work?

Spark Plasma Sintering (SPS) stands at the forefront of advanced materials processing, offering a revolutionary method for compacting and sintering powder materials. This cutting-edge technology has gained prominence across diverse industries, from aerospace to biomedical engineering. Let's delve into the inner workings of Spark Plasma Sintering and explore how it achieves precision and efficiency in material synthesis.

Understanding Spark Plasma Sintering (SPS)

1. Introduction to SPS Technology:

Spark Plasma Sintering, also known as Field-Assisted Sintering Technique (FAST), is a consolidation process that involves the application of pulsed direct current (DC) and uniaxial pressure to powder materials. Unlike traditional sintering methods, SPS operates at a significantly faster rate and lower temperatures.

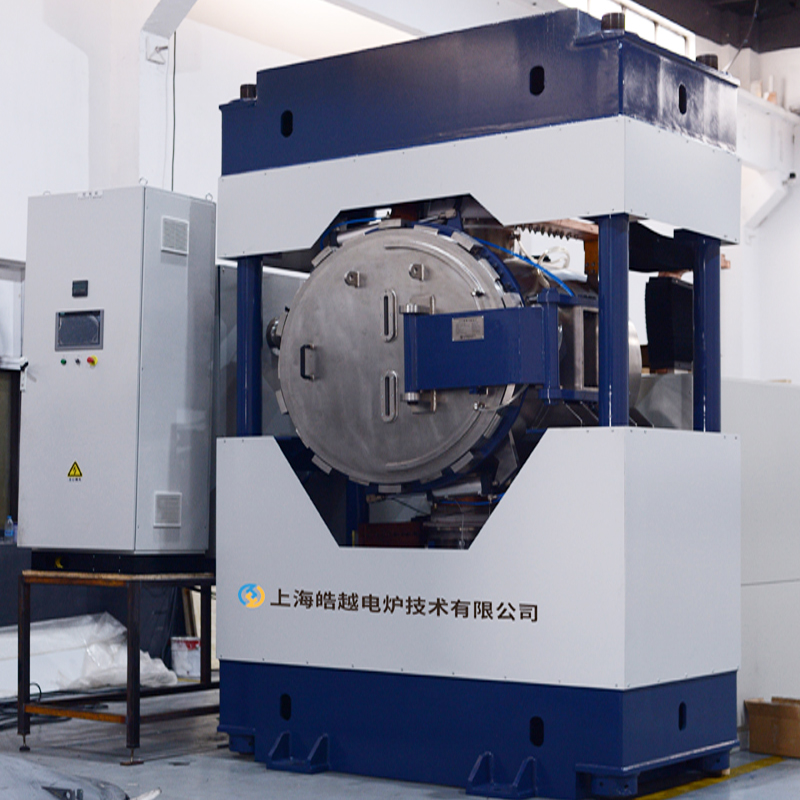

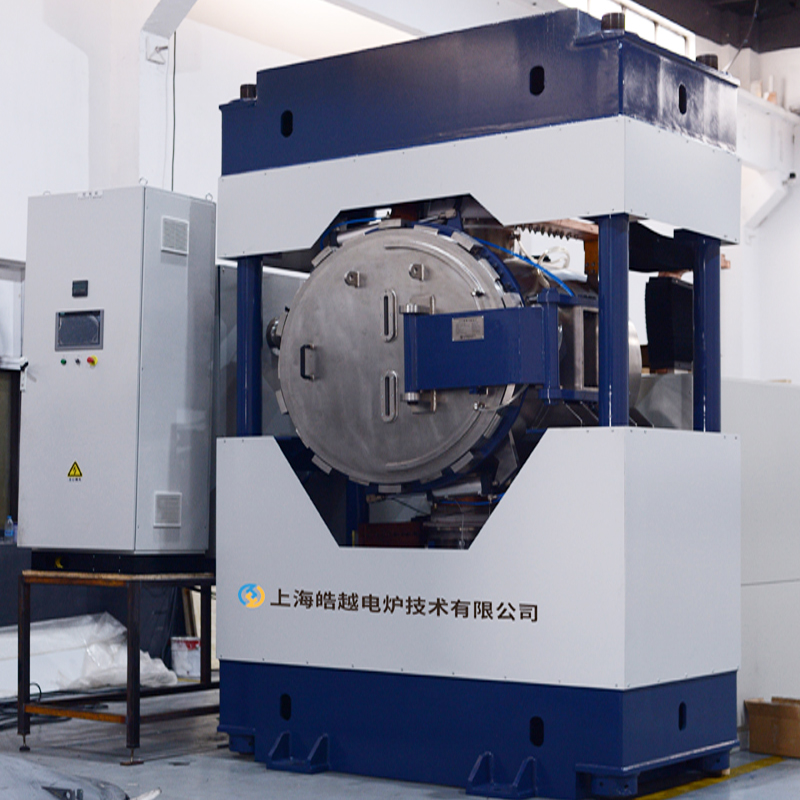

2. The SPS Setup:

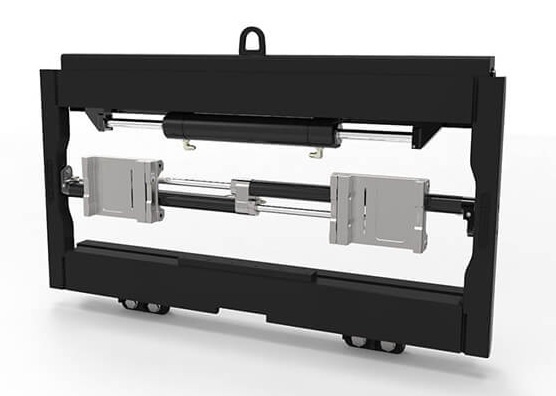

Powder Arrangement: The process begins with the arrangement of the powder material in a die.

Graphite Die: The die typically consists of a graphite material to withstand high temperatures and electrical conductivity.

Pressure Application: Uniaxial pressure is applied to the powder compact to ensure a uniform density.

3. Pulsed Direct Current (DC):

Introduction of Current: Pulsed DC is applied to the graphite die, creating intense electrical fields within the powder material.

Die Heating: The electrical resistance within the die generates heat, rapidly increasing the temperature of the powder particles.

4. Spark Plasma Effect:

5. Benefits of Spark Plasma Sintering:

High Heating Rates: SPS achieves heating rates on the order of hundreds of degrees per minute, significantly faster than traditional sintering methods.

Lower Sintering Temperatures: The localized heating allows for sintering at lower temperatures, preserving the properties of temperature-sensitive materials.

Enhanced Densification: The combination of pressure and plasma heating promotes thorough and uniform densification of the powder.

6. Applications Across Industries:

Materials Science: SPS is widely used for the fabrication of advanced ceramics, composites, and functional materials.

Biomedical Engineering: In the production of bioresorbable implants and dental prosthetics.

Aerospace: For manufacturing components with complex geometries and high-performance materials.

7. Challenges and Considerations:

Uniformity: Achieving uniform densification across large or complex-shaped samples can be a challenge.

Cost: The equipment and initial setup costs for SPS can be higher compared to conventional sintering methods.

Spark Plasma Sintering has emerged as a transformative technique, pushing the boundaries of materials synthesis. Its ability to rapidly and efficiently sinter a diverse range of materials makes it a valuable asset in the pursuit of advanced material properties. As technology continues to evolve, Spark Plasma Sintering promises to play a pivotal role in shaping the future of materials engineering.

Featured content:What is the Difference Between a Condenser and a Cooling Tower?How To Select the Right Tube Polishing MachinesWhat is the cost of automatic EPS shape molding machine?Quality Control in Maize Flour Milling Plants: Ensuring Excellence in StandardsHow to select a Gold Melting FurnaceRevolutionizing Manufacturing: The Automatic EPS Shape Molding MachineWhat is a CO2 Tank Used For?

Comments

Please Join Us to post.

0