The name of the tape used in underground pipe wrapping is called corrosion protection tape. It is a vital material used to protect underground pipelines from corrosion and extend their lifespan.

### Step 1: Prepare the Pipe Surface.

Before applying the corrosion protection tape, it is important to clean and prepare the surface of the pipe. Remove any dirt, rust, or paint using a wire brush or sandpaper. Ensure that the surface is dry and free from any contaminants.

### Step 2: Apply Primer.

Once the surface is clean, apply a primer to promote adhesion between the pipe and the corrosion protection tape. The primer helps create a strong bond and enhances the effectiveness of the tape in preventing corrosion.

### Step 3: Wrap the Pipe.

Unroll the corrosion protection tape and start wrapping it around the pipe in an overlapping manner. Ensure that each layer overlaps the previous one by at least 50%. Press the tape firmly onto the pipe to ensure proper adhesion.

### Step 4: Apply Heat.

Featured content:Are there any limitations to using Hydroxypropyl Methylcellulose (HPMC) For Tile Adhesive?How can High Performance Materials benefit me?Which is the best P 1019 primer?Ultimate Guide to Galvanized Steel Coil for Infrastructure: Benefits & ApplicationsHow do I choose a 3-wire steel strand?Mastering Makeup with P 1019 Primer Guide10 Reasons Why PPGL Coil Beats Traditional Refrigerator PanelsSome types of corrosion protection tape require heat activation to form a secure bond with the pipe. Use a torch or heat gun to carefully heat the wrapped tape, following the manufacturer's instructions. Be cautious not to overheat the tape.

### Step 5: Inspect the Wrap.

Once the tape is applied and heated, inspect the wrap for any gaps, wrinkles, or areas where the tape is not properly adhered to the pipe. Make any necessary adjustments or add additional tape to ensure complete coverage.

### Step 6: Test the Wrap.

After completing the wrapping process, perform a test to ensure the effectiveness of the corrosion protection tape. This may involve conducting a pressure test or using other methods to check for leaks or corrosion.

### Step 7: Monitor and Maintain.

Regularly monitor the condition of the corrosion protection tape on the underground pipes. Inspect for any signs of damage, wear, or corrosion, and make repairs or replacements as needed to ensure continued protection.

By following these steps and using corrosion protection tape correctly, you can effectively safeguard underground pipes from corrosion and ensure their long-term durability.

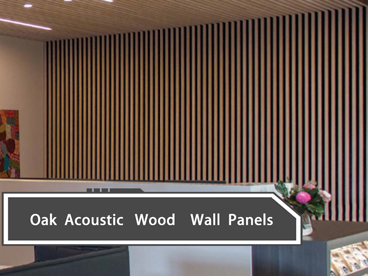

If you want to learn more, please visit our website Car Soundproofing Insulation Tape, aluminum foil waterproof cold applied tape, Pipeline Anti Corrosion Tape.

Featured content:The Eco-Friendly Solution: Biodegradable Ziplock Bags ExplainedHow does Corrosion Prevention Tape work effectively?5 Innovative Ways to Use Embossed Metal Sheets for Home DecorHow to properly install PC strand?4 Advice to Choose a 2mm Aluminum Foil Waterproof Cold Applied TapeMelting Deicing Device: An Innovative Solution for Winter SafetyDancing Fountain Design: The Art of Harmonizing Water and Architecture

Comments

Please Join Us to post.

0