Welcome to the world of engine test benches, where precision meets performance. In this comprehensive guide, we'll delve into the intricate workings of these technological marvels and explore how they play a pivotal role in the automotive and aerospace industries.

What is an Engine Test Bench?

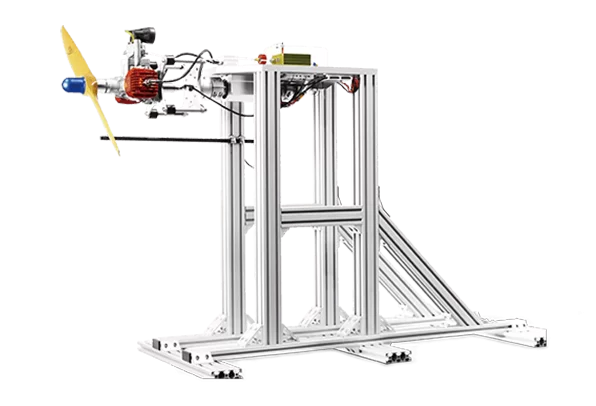

An engine test bench is a sophisticated apparatus designed to evaluate and analyze the performance of internal combustion engines. Unlike conventional engines installed in vehicles, an engine test bench provides a controlled environment, allowing engineers to scrutinize every aspect of an engine's functionality without the need for an actual vehicle.

Components of an Engine Test Bench

1. Engine Dynamometer

At the heart of every engine test bench lies the engine dynamometer. This essential component measures the engine's output, torque, and power, providing invaluable data for performance analysis. High-precision sensors ensure accurate readings, enabling engineers to fine-tune and optimize engine parameters.

2. Data Acquisition System

A state-of-the-art engine test bench is equipped with an advanced data acquisition system. This system gathers real-time information on various parameters, such as fuel consumption, exhaust emissions, and temperature. This wealth of data aids engineers in making informed decisions to enhance efficiency and reduce environmental impact.

3. Control and Monitoring Unit

Efficient control is paramount during testing. The control and monitoring unit allows engineers to manipulate engine parameters, mimicking different operating conditions. This level of control is instrumental in assessing an engine's performance across a spectrum of scenarios.

How Does an Engine Test Bench Work?

1. Preparation and Setup

Before the engine roars to life on the test bench, meticulous preparation is required. This involves securing the engine in place, connecting sensors, and configuring the dynamometer for the upcoming tests.

2. Test Execution

With all systems ago, the engine undergoes a series of meticulously planned tests. These can range from endurance tests and performance assessments to emissions analysis. The data acquisition system records every nuance, providing a comprehensive overview of the engine's behavior.

3. Data Analysis

Post-testing, engineers dive into the collected data, analyzing performance metrics and identifying areas for improvement. This phase is crucial for refining engine designs, enhancing fuel efficiency, and meeting stringent emission standards.

Applications of Engine Test Benches

Automotive Industry

In the automotive sector, engine test benches are indispensable for developing and fine-tuning engines before they hit the road. From compact cars to high-performance vehicles, manufacturers rely on these test benches to ensure optimal engine performance and reliability.

Aerospace Industry

The aerospace industry also harnesses the power of engine test benches. Jet engines, propellers, and auxiliary power units undergo rigorous testing to meet safety and performance standards. This meticulous testing process ensures the reliability of engines in the challenging conditions of flight.

Advantages of Engine Test Benches

Efficiency Enhancement

By subjecting engines to a controlled environment, engineers can identify inefficiencies and implement optimizations. This results in engines that are not only powerful but also fuel-efficient.

Cost Savings

Detecting potential issues in the early stages of development through testing can lead to significant cost savings. Addressing problems before mass production mitigates the need for expensive recalls and repairs.

In conclusion, the engine test bench stands as a testament to precision engineering and technological innovation. Its role in shaping the future of automotive and aerospace industries cannot be overstated. By unlocking the secrets of engine performance in a controlled setting, engineers pave the way for more efficient, powerful, and environmentally friendly engines.

Comments

Please Join Us to post.

0