Introduction:

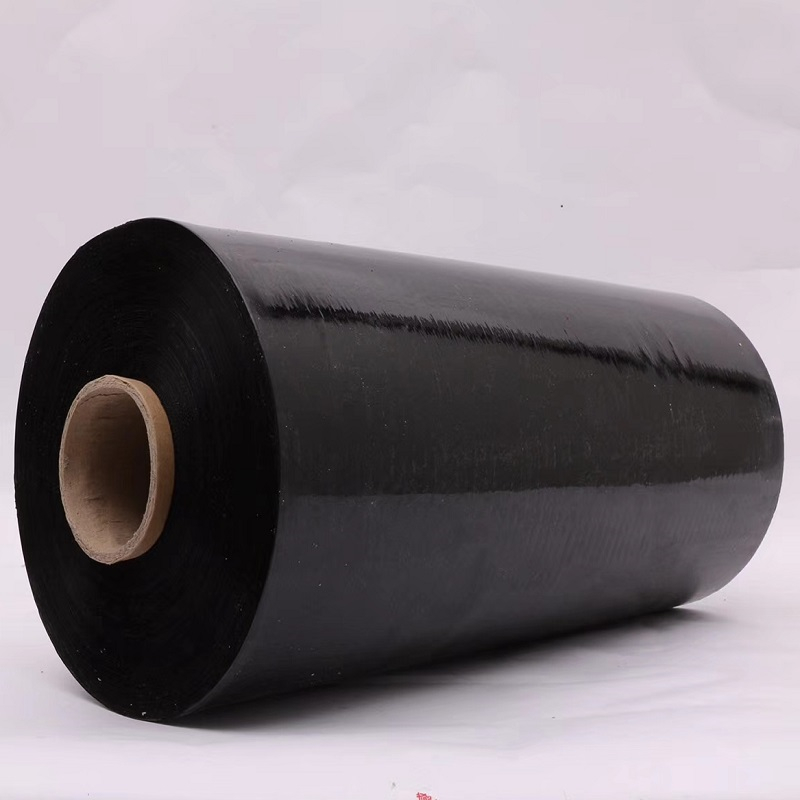

Stretch film, also known as stretch wrap, has become an indispensable tool in the world of packaging and logistics. This thin plastic film is designed to stretch and tightly wrap around products or pallets, providing a secure and protective layer. In this article, we will explore the versatility and numerous benefits of stretch film, shedding light on its crucial role in ensuring efficient and safe packaging and logistics operations.

1. Versatile Packaging Solution

Stretch film offers a versatile packaging solution for a wide range of industries and applications. It can be used to bundle small items together, protect fragile goods from dust and moisture, or secure larger loads on pallets. From retail and food industries to manufacturing and distribution centers, stretch film provides a flexible packaging option that adapts to various shapes and sizes.

2. Enhanced Product Protection

One of the key benefits of stretch wrap film is its ability to provide superior product protection. The film's elastic properties allow it to conform closely to the contours of the packaged items, creating a tight and secure wrap. This offers excellent resistance against dirt, dust, moisture, and other external elements that could potentially damage the goods during storage or transportation. By safeguarding the products, stretch film helps to maintain their quality and integrity.

3. Improved Stability and Load Integrity

Stretch film plays a vital role in ensuring load stability and integrity. When applied correctly, it tightly secures the products or pallets together, preventing shifting, tilting, or collapsing during handling or transit. This reduces the risk of damage and minimizes product loss. Additionally, the stability provided by stretch film enables efficient stacking of pallets, optimizing warehouse space utilization and facilitating safer transportation.

Featured content:Exploring the Durability of Stainless Steel Cable TiesCharacteristics of Glass Liquor BottlesDo black glass jars with lids come in different sizes?Advantages and Benefits of Using Sticky Sublimation PaperPet Foods Packaging: Ensuring Quality and Convenience for Your Furry FriendsAdvantages and Disadvantages of Dye InkWhat is cold forming process in blister packaging?4. Cost-Effective Solution

Stretch film offers cost-effective packaging and logistics solutions. Its lightweight nature helps to minimize the overall weight of the packaging, reducing shipping costs. Furthermore, stretch film requires less material compared to traditional packaging methods such as strapping or taping. This results in cost savings on packaging materials and lower labor costs due to its quick and efficient application process.

5. Improved Efficiency and Productivity

With its ease of use and efficient application process, stretch film enhances operational efficiency and productivity. It can be applied manually or with automated machinery, saving time and reducing labor efforts. The ability to wrap products or pallets in one continuous motion increases packaging speed and throughput. This allows businesses to optimize their packaging processes, meet tight deadlines, and improve overall productivity.

6. Sustainability Considerations

As environmental sustainability gains importance, stretch film manufacturers have developed eco-friendly alternatives. These options include biodegradable films and films made from recycled materials. Choosing sustainable stretch film contributes to reducing the environmental impact associated with packaging waste. Furthermore, the lightweight nature of stretch film results in fewer materials used and lower carbon emissions during transportation.

Stretch film has revolutionized the packaging and logistics industry, offering a versatile, cost-effective, and efficient solution for product protection, stability, and load integrity. Its ability to tightly wrap around products or pallets ensures enhanced product safety during storage and transportation. Stretch film improves operational efficiency, reduces packaging costs, and contributes to sustainable packaging practices. Whether in retail, manufacturing, or distribution, stretch film continues to be a vital tool in ensuring efficient and secure packaging and logistics operations.

Featured content:What Size Tarp for Camping?What factors should I consider when selecting the right size and capacity of glass liquor bottles for my product?What factors should businesses consider when choosing the right IML packaging solution for their specific products?How can I ensure the glass bottles I purchase meet quality standards and regulations?The Versatility of Kraft Paper Popcorn BagsHow does Kraft wrapping paper promote eco-friendly and sustainable packaging practices?What Is Retort Pouch Packaging?

Comments

Please Join Us to post.

0