In the field of fluid control and piping systems, check valves play a vital role in ensuring the smooth and efficient operation of various industries. These humble devices allow fluid to flow in one direction while preventing backflow, making them vital components in pipes, pumps, and all kinds of machinery. In this article, we will explore the requirements of check valves, delving into the key considerations and factors that engineers and industry professionals must keep in mind when selecting and designing these critical components.

What Is a Check Valve?

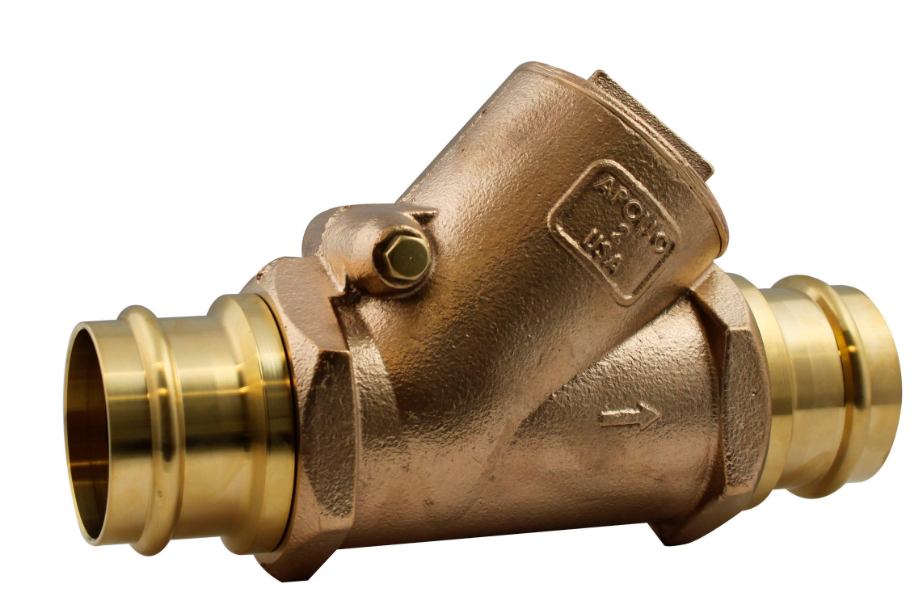

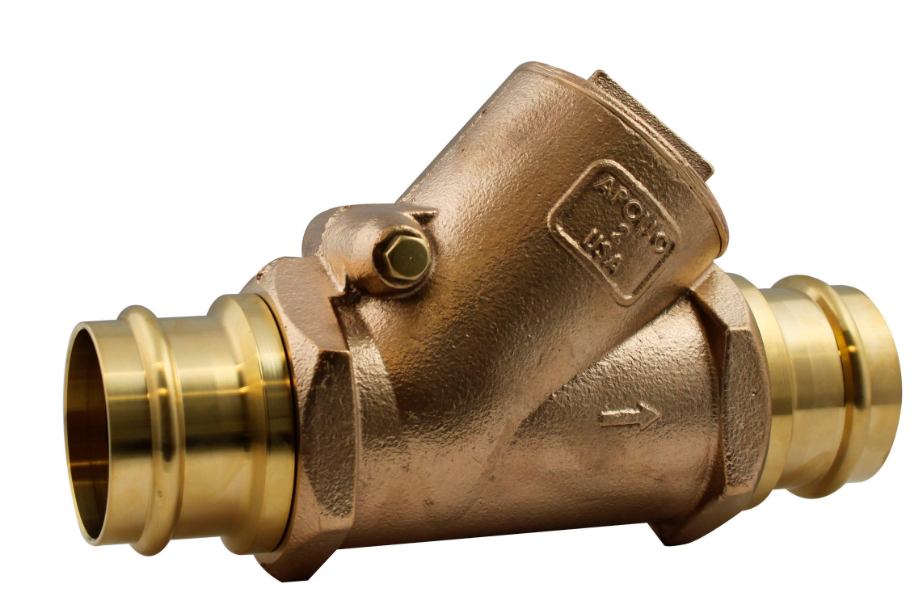

A check valve is a mechanical device engineered to facilitate the unidirectional flow of fluids. These valves are equipped with two fundamental ports: an inlet and an outlet. Their primary role is to thwart any undesired backflow of fluids within a wide array of industrial applications.

Key Requirements for an Effective Check Valve

When selecting or designing a check valve, several key requirements must be met to ensure optimum performance. These requirements can be grouped into five main areas:

1. Reliable sealing mechanism

One of the basic requirements of check valves is a reliable sealing mechanism. When the valve is closed, it must provide a tight seal to prevent any backflow or leakage. The type of sealing mechanism used, whether ball, disc or disc, should be selected based on the specific application and fluid properties.

2. Low pressure drop

In fluid systems, where efficiency is paramount, a check valve should offer minimal resistance to flow. Low pressure drop is critical to ensure the system operates at maximum efficiency and minimum energy consumption.

3. Fast response time

Featured content:Are Chinese bearings any good?How Do You Determine Wire Mesh Size?Ductile Iron Pipe vs. PVC Pipe: A Comparative AnalysisEverything You Need to Know About 80 Tooth Carbide BladeWhere rapid changes in flow direction occur, such as in pump systems, check valves must have a fast response time. Delayed response may lead to water hammer or other undesirable consequences.

4. Durability and longevity

Check valves are often exposed to harsh conditions and used frequently. Therefore, they must be made of materials that can withstand long-term corrosion, erosion and wear. Stainless steel, brass, and durable plastics are common materials used for this purpose.

5. Compatibility with Fluid Properties

Different fluids have different properties including temperature, viscosity and chemical composition. A well-designed check valve should be compatible with the specific fluid it handles. For applications involving aggressive chemicals or extreme temperatures, specialized check valves may be required.

The Importance of Proper Sizing and Installation

Choosing the correct size and installing the check valve correctly is just as important as meeting the above requirements. Improper sizing can result in flow restriction, while incorrect installation can cause premature wear and loss of performance. It is recommended to consult an expert or use sizing software to determine the optimum check valve size for a given application.

In conclusion

To sum up, the check valve is an important part of the fluid control system, which has the key function of preventing backflow, ensuring the efficiency and safety of pipelines and machinery. To meet check valve requirements, engineers and industry professionals must consider factors such as reliable sealing, low pressure drop, fast response time, durability, and compatibility with fluid properties. Proper sizing and installation further enhances the effectiveness of these important components.

Featured content:Fiberglass Telescopic Pole: A Durable and Versatile Tool for Height Access

Comments

Please Join Us to post.

0