Woven and welded wire mesh may look similar to the untrained eye, but while they share some characteristics, the materials are distinctly different.

How do you know which one is right for your next project? Find a rundown of each metal mesh product below, along with pointers for choosing a material that best suits your needs.

What is woven wire mesh?

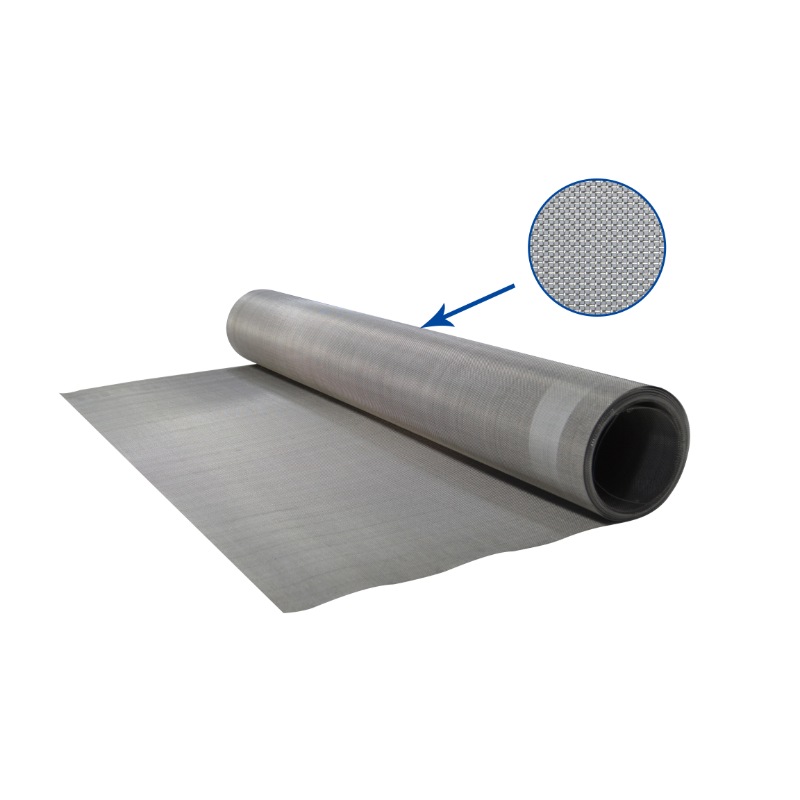

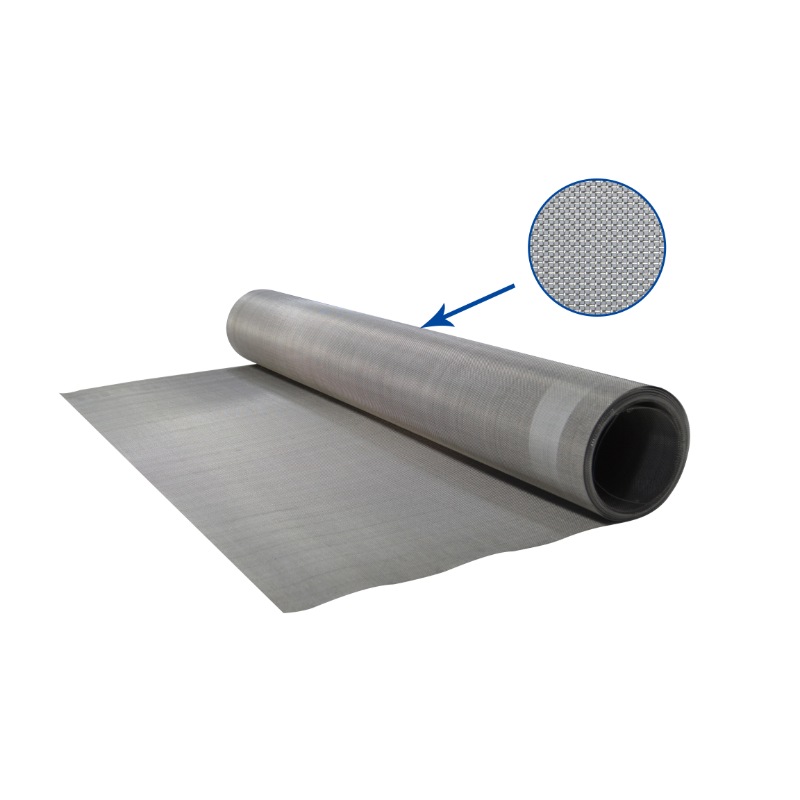

Woven wire mesh is a metal grid with intersecting vertical (warp) and horizontal (weft) wires that create square-shaped (or sometimes hexagonal) openings. Since the wires only intersect rather than being welded or otherwise fixed together, this type of mesh is typically flexible and easy to manipulate. Though woven mesh is often pliant, it can be more rigid when made with thicker wires.

How is woven mesh made?

The mesh is typically made using an industrial loom (sometimes called a weaving machine). Wires are wrapped around a warp beam, then placed into a heddle frame. This separates the warp wires so they can pass through another set of weft wires and create a grid pattern of a specified size.

What is it used for?

A wide range of applications call for woven wire mesh. This is especially true when it comes to home improvement and DIY projects. The material is a go-to for everything from gardening, composting, and craft papermaking to pest control, insect screens, and food drying. Artistic DIYers can even use this bendable mesh to create decorative sculptures.

In the industrial sector, it's often used for filtration, screen printing, and particle analysis.

What is Welded Wire Mesh?

Welded wire mesh is a stainless steel grid with intersections fused together with heat. This material is not malleable but rather rigid and notably strong, maintaining its structure under heavy pressure.

How is welded mesh made?

Welded wire mesh is made by first feeding opposing (warp and weft) wire spools through a special welding loom. The machine lays the horizontal wires over the vertical wires to create a grid, then it applies heat to the intersections to fuse the crossing wires together.

What is it used for?

Unlike woven wire mesh, the welding process calls for thicker metal wires. This sturdy, inflexible material is ideal for fencing, chicken coops, and animal enclosures. It can also be used for soffit screens, foundation vents, chimney caps, gabions, trellises, and automotive grills.

In the engineering and construction sectors, stainless steel welded mesh is used for infill panels, landslide mitigation, and highway reinforcement.

Which Wire Mesh is Best, Woven or Welded?

Welded wire mesh is constructed with thicker wires and is available in larger opening sizes. This material can be used for structural purposes when projects call for durable metal grids.

Woven wire mesh, on the other hand, is available in much finer weaves (including many decorative styles), which makes it useful for cabinet inserts, insect screens, and more.

If you need a large, rigid metal mesh panel with reliable strength, go with welded mesh. If you need something with much smaller openings or that can be manipulated into different shapes, woven mesh is a better choice.

Shop DIY & Industrial Metal Wire Mesh Products

TWP Inc. has been a trusted supplier of wire mesh products for over 50 years. We carry a huge selection of materials, including woven mesh, welded panels, and galvanized hardware cloth—all in stock and ready to ship.

If you're still not sure what type or size you need, we're here to assist. Contact us today!

Want to have your project featured in our online gallery? Share your photos on Instagram using the hashtag #TWPWireMesh.

What is woven wire mesh and welded wire mesh?

Something went wrong. Wait a moment and try again.

What is woven wire mesh?

A woven wire mesh, also known as a woven wire cloth, is made by weaving wire strands in an overunder method or underover method to form different patterns with varying specifications. Some of the most common weave patterns are explained below.

Mesh weave pattern has a significant impact on which use cases it is suitable for. In general, square weaves are well suited for general-purpose applications, while dutch weaves are better suited for air and water filtration.

The size and material of woven wire mesh vary in addition to the weave. Various opening sizes are available, from just a few microns to several inches, as well as metals including aluminium, brass copper and mild steel.

We hope that this page explains woven mesh for you. This image shows a standard plain stainless steel woven wire mesh panel.

Comments

Please Join Us to post.

0