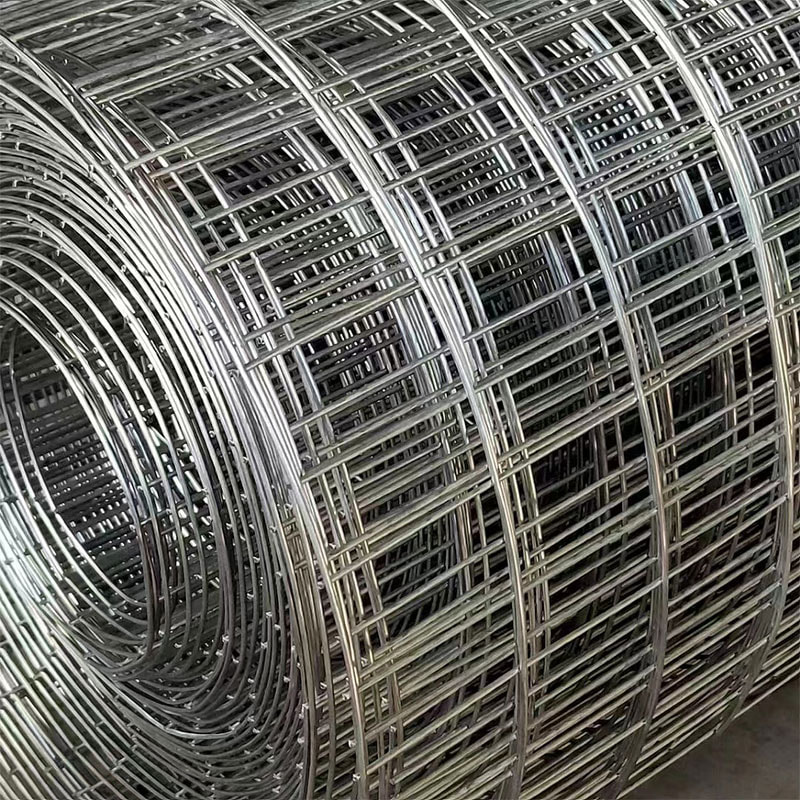

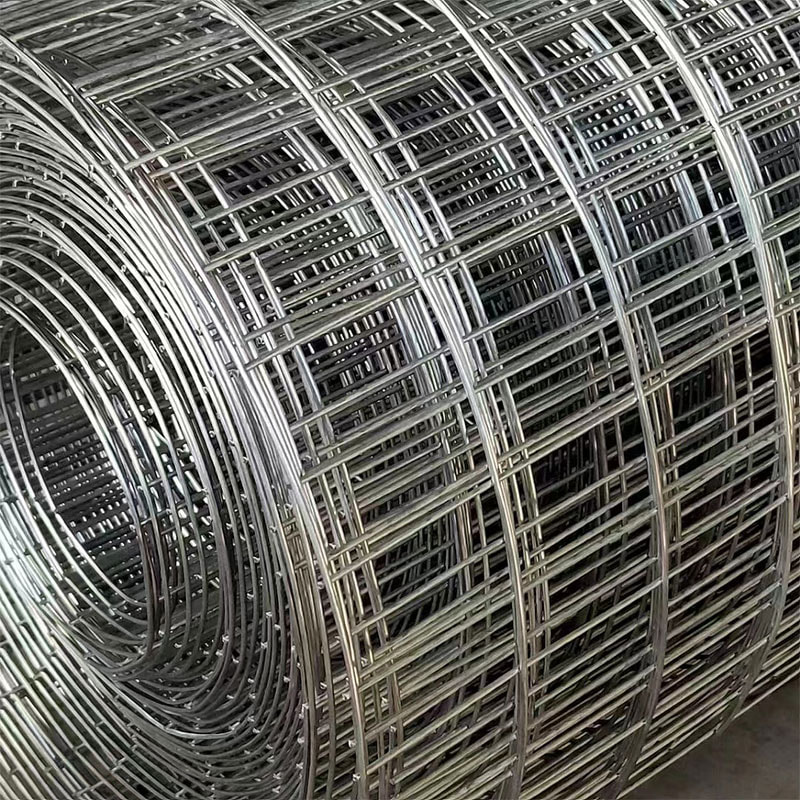

Stainless steel welded wire mesh is a versatile and widely used material in various applications due to its unique properties. Here are some advantages and disadvantages of using stainless steel welded wire mesh:

Advantages:

Corrosion Resistance: Stainless steel is highly resistant to corrosion, making it an ideal choice for applications in harsh and corrosive environments, such as marine or chemical industries.

Durability: Stainless steel is known for its durability and long lifespan, which reduces the need for frequent replacements and maintenance.

Strength: Stainless steel wire mesh has excellent tensile strength, making it suitable for applications that require structural integrity and load-bearing capacity.

Hygienic: Stainless steel is easy to clean and sterilize, making it a preferred choice in industries where hygiene is crucial, such as food processing and healthcare.

Aesthetic Appeal: Stainless steel wire mesh has a sleek and modern appearance, making it suitable for architectural and decorative applications.

Thermal Stability: Stainless steel maintains its strength and integrity at high temperatures, making it suitable for applications involving extreme heat.

Welded Construction: The welded construction of the mesh provides a stable and secure structure, ensuring the mesh maintains its shape and integrity.

Disadvantages:

Cost: Stainless steel is generally more expensive than other materials like mild steel or galvanized steel, which can make it less cost-effective for some applications.

Weight: Welding wire mesh is heavier than some other materials, which may limit its use in applications where weight is a concern.

Fabrication Challenges: Welding stainless steel can be more challenging than welding other materials, requiring skilled labor and specialized equipment.

Magnetism: Some grades of stainless steel can exhibit magnetic properties, which may not be suitable for applications where magnetism is a concern.

Conductivity: Stainless steel is not an ideal choice for applications that require good electrical conductivity, as it is a poor conductor of electricity.

Limited Availability: Depending on your location, certain grades and specifications of stainless steel wire mesh may not be readily available, leading to longer lead times and higher costs.

Appearance Changes: While stainless steel is generally resistant to rust and corrosion, it can develop surface discoloration or staining over time in certain conditions.

In summary, stainless steel welded wire mesh offers many advantages, primarily its corrosion resistance, durability, and strength. However, its higher cost and weight, as well as specific challenges in fabrication, may limit its use in certain applications. Careful consideration of the specific requirements of your project is essential when choosing stainless steel wire mesh or any other material.Learn more

Comments

Please Join Us to post.

0