What is UHMWPE pipe?

UHMWPE pipe, also known as ultra-high molecular weight polyethylene pipe, is a pipe formed by continuous extrusion of ultra-high molecular weight polyethylene (UHMWPE) resin with a molecular weight greater than 2.5 million. Under the conditions of strong corrosion and high wear, the service life is 4-6 times that of steel pipes, which fully demonstrates the advantages of 'energy saving, environmental protection, economy and high efficiency'.

Are you interested in learning more about flanged uhmwpe pipe? Contact us today to secure an expert consultation!

Properties of UHMWPE pipes

Type

Item

UHMW-PE

Physical Properties

Relative molecular weight/ million

2-3

Density/ (g/cm3)

0.945-0.975

Grain size/ mesh

40-200

Mechanical Properties

Tensile yield stress/ MPa

'20

Fracture Extensibility %

300-400

Flexural Modulus/ MPa

600

Impact Strength/ (KJ/m)

>140

Rate of Wear % (23±2) '

'0.4

Thermal Properties

Melting Point/ '

136

Distortion Temperature/ '

85

Thermal Conductivity/ [w/(m.v)]

8.5

Electrical Properties

Mass Resistivity/ (cm)

10

Punch Through Voltage/ (Kv/mm)

50

Contact us to discuss your requirements of light weight hdpe dredging pipe. Our experienced sales team can help you identify the options that best suit your needs.

Featured content:FKM vs Nitrile: Which material is right for your applications?Method and application of sand blasting hose - OrientflexWhen to Use China Hydraulic Rubber Hose?What is Metal Corrugated Compensator and Why Do We Use Them?The Ultimate Guide to OEM Smooth Hydraulic HoseEverything You Need to Know About 100R3 HoseUltimate Guide: How to Save Money on Hydraulic Hoses?

Dielectric Constant

2.3

Advantages of UHMWPE Pipes:

- High wear resistance: 4 times of steel pipe, 3 times of common PE pipe and 4 times of nylon pipe. It is proved that UHMWPE pipe is a common wear-resistant pipe for small particle slurry transportation.

- High corrosion resistance: UHMWPE is saturated intermolecular structure, so its chemical stability is extremely high and can resist various corrosive media (acid, alkali, salt) and organic solvents in the environment.

- Weather resistance and aging resistance: UHMWPE pipes have good weather resistance and aging resistance. Because there are very few unsaturated groups in the molecular chain of UHMWPE and the molecular weight is large, the pipe can maintain more than 70% of its mechanical properties for up to 50 years even after about 70% use.

- High flexibility: The elongation at break can reach more than 400%, and there is a large bending during construction, and the subsidence of the earth's crust can elongate up to 3 times without breaking.

- High impact resistance: The impact resistance and impact energy absorption of ultra-high molecular weight polyethylene (UHMWPE) pipes rank first among plastics, and they are not easy to crack regardless of external force or internal pressure fluctuations. The impact strength is 10 times that of nylon 66 and 4 times that of polyethylene PE100.

- Good energy-saving effect: The friction coefficient is 0.07-0.11 , the roughness is only 1/6 of the new steel pipe, the circulation capacity is more than 50% higher than that of steel pipe, and the inner diameter of steel pipe can be reduced by about 15% compared with that of steel pipe.

- Easy to install: The weight of UHMWPE pipe is 1/8 of steel pipe, which greatly reduces the installation cost. The pipe body is directly flanged and connected with flange butt, no need to add seals; it can also be inserted into hot melt welding, with high interface strength and easy operation.

- Long service life: Under the same operating conditions, the wear resistance of UHMWPE pipes is 4 to 7 times higher than that of Q235 steel pipes, or 10 times that of HDPE (PE100) pipes, and the service life of UHMWPE pipes is longer under most operating conditions Much longer.

4 common identification methods:

1. Weight

The density of UHMWPE products is between 0.93-0.95g/cm3, which can float on water. If it is not pure UHMWPE material, the product will sink into water.

2. Temperature

Good quality UHMWPE products will not melt and deform at 200°C, but will become soft. Inferior UHMWPE products will deform at 200 °C.

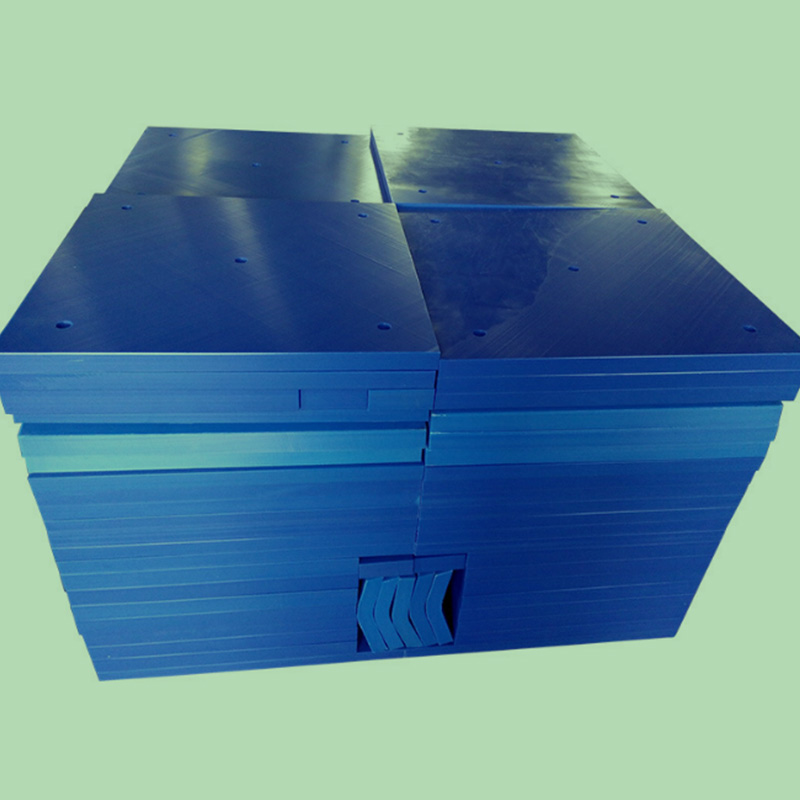

3. Visibility

The surface of good-quality UHMWPE pipe is smooth, neat, black and bright, and the cross-sectional density is very uniform. The surface color of inferior UHMWPE pipes is dull, and the cross-sectional density is uneven.

4. UHMWPE Pipe Ends

Good UHMWPE pipe ends are smooth, uniform, and have good roundness and verticality, but poor-quality UHMWPE pipes will crack and peel off after the pipes are heated.

Related News

Compression and application of UHMWPE

Compression molding, as mentioned earlier, is also employed for UHMWPE processing. In compression molding, the molten UHMWPE is placed into a heated mold and compressed under pressure until it solidifies. This method is suitable for manufacturing larger components or parts that require specific configurations. These processing techniques allow UHMWPE to be molded into various forms, including sheets, rods, tubes, profiles, and intricate components. The choice of processing method depends on the desired shape, size, and mechanical properties required for the specific application. In the subsequent sections, we will explore the specific applications of UHMWPE in industries such as medical and healthcare, automotive and transportation, sports and recreation, industrial and chemical processing, as well as the food and beverage industry. Stay tuned to discover the diverse applications of this exceptional engineering plastic.

Applications of UHMWPE

Ultrahigh Molecular Weight Polyethylene (UHMWPE) finds extensive use in various industries due to its exceptional properties and versatile nature. Let's explore some of

the key applications of UHMWPE across different sectors.

1.

Medical and Healthcare Industry

In the medical and healthcare industry, UHMWPE has revolutionized orthopedic implants. It is commonly used in joint replacements, such as hip and knee implants. UHMWPE's biocompatibility, low wear rate, and ability to withstand the demanding forces and friction within the human body make it an ideal material for long-lasting and reliable orthopedic devices. It offers patients improved mobility, reduced pain, and enhanced durability.

2.

Automotive and Transportation

UHMWPE plays a vital role in the automotive and transportation sector. Its lightweight nature, high impact strength, and excellent chemical resistance make it an ideal material for various applications. It is used in components like gears, bearings, bushings, and liners, contributing to reduced weight, improved fuel efficiency, and enhanced performance. Additionally, UHMWPE's low friction coefficient and wear resistance make it suitable for applications like wear strips, slider pads, and truck bed liners.

3.

Sports and Recreation

The sports and recreation industry benefits greatly from the unique properties of UHMWPE. It is used in the manufacturing of ski and snowboard bases, providing excellent gliding properties, durability, and resistance to abrasion. UHMWPE is also utilized in protective gear, such as helmets and padding, due to its impact resistance and toughness. Additionally, its low friction coefficient makes it suitable for applications like playground equipment, ice rink boards, and synthetic ice surfaces.

4.

Industrial and Chemical Processing

UHMWPE is widely employed in industrial and chemical processing applications. Its excellent chemical resistance and low friction properties make it ideal for lining pipes, tanks, and chutes in chemical plants and processing facilities. UHMWPE's ability to withstand corrosive substances, high temperatures, and abrasive materials ensures longevity and reliability in harsh industrial environments. It is also used as a material for conveyor components, seals, gaskets, and wear-resistant parts.

5.

Food and Beverage Industry

In the food and beverage industry, UHMWPE plays a crucial role in ensuring safety, efficiency, and hygiene. It is widely used for food processing equipment, conveyor belts, cutting boards, and packaging machinery. UHMWPE's low moisture absorption, excellent chemical resistance, and ease of cleaning make it suitable for maintaining strict sanitary standards. Its non-toxic nature and resistance to bacterial growth further enhance its suitability for food contact applications.

These are just a few examples of the extensive applications of UHMWPE. Its unique combination of properties makes it a versatile and sought-after material in numerous industries, ranging from medical and automotive to sports, industrial, and food processing. As technology advances, UHMWPE continues to explore new frontiers, expanding its reach and unlocking innovative applications.

In the upcoming sections, we will discuss the comparison of UHMWPE with other engineering plastics, maintenance and care of UHMWPE products, and future trends and developments in the field. Stay tuned to stay updated on the latest advancements and insights related to UHMWPE.

The company is the world’s best hdpe pipe floater supplier. We are your one-stop shop for all needs. Our staff are highly-specialized and will help you find the product you need.

Comments

Please Join Us to post.

0