Corediam are exported all over the world and different industries with quality first. Our belief is to provide our customers with more and better high value-added products. Let's create a better future together.

Chainsaws are powerful tools that have become an essential part of many people's toolkit. Whether you are a professional logger, a homeowner with a lot of trees, or just someone who likes to work on DIY projects, having a chainsaw can make your life a lot easier. But have you ever wondered how chainsaws actually work? In this blog post, we will take a closer look at the inner workings of a chainsaw and explore how they operate.

At first glance, a chainsaw may seem like a simple machine. It has a motor, a chain, a guide bar, and a handle. However, underneath this seemingly straightforward design lies a complex system of moving parts and mechanisms that work together to make the chainsaw function effectively.

The heart of a chainsaw is its engine, which can be powered by electricity, gasoline, or battery. The engine provides the power necessary to drive the chain around the guide bar at high speeds, allowing it to cut through wood with ease. The engine is typically located at the rear of the chainsaw and is connected to the chain via a system of gears and sprockets.

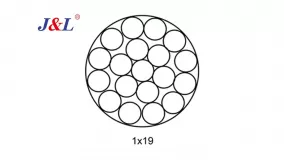

The chain is what actually does the cutting in a chainsaw. It consists of a series of sharp teeth that rotate around the guide bar when the engine is running. The chain is lubricated by oil from a reservoir inside the chainsaw, which helps reduce friction and prolong the life of the chain. The teeth on the chain are designed to cut through wood quickly and efficiently, making the chainsaw a powerful tool for any cutting job.

The guide bar is a long, flat piece of metal that provides support for the chain and helps guide it through the wood. It is usually made of high-strength steel or aluminum to withstand the high speeds and forces generated by the chain. The guide bar is attached to the chainsaw body and extends out in front of the engine, allowing the chain to reach the wood being cut.

Featured content:Corded vs Cordless Tools - Which is Better?The Art of Precision: Enhancing Walls with Paint TapeWhat kind of roller do you use for epoxy flooring?Why are diamond blades so cheap?What is the lifespan of a diamond drill bit?A Step-by-Step Guide on How to Use Ratchet StrapsWhat is a PCD grinding wheel?The handle of the chainsaw is where the operator grips the tool and controls its movements. It is typically located at the front of the chainsaw body and is designed to be comfortable and easy to hold. The handle may have trigger controls for starting and stopping the engine, as well as safety features such as a chain brake or kickback guard to protect the operator from any accidents.

So how does a chainsaw actually cut through wood? When the engine is started, the chain begins to rotate around the guide bar at high speeds. The sharp teeth on the chain bite into the wood, creating small chips and sawdust as they move through the material. The operator guides the chainsaw along the wood, controlling the speed and direction of the cut to achieve the desired result.

The efficiency and effectiveness of a chainsaw depend on a variety of factors, including the size and power of the engine, the sharpness of the chain, and the quality of the guide bar. Regular maintenance and care are essential to keeping a chainsaw in good working condition and ensuring it performs at its best.

In conclusion, chainsaws are powerful tools that can make cutting wood a breeze. By understanding how chainsaws work and how they are designed, you can better appreciate the engineering and craftsmanship that goes into making these machines. Whether you are using a chainsaw for professional logging or just cutting firewood in your backyard, having a basic understanding of how chainsaws operate can help you make the most of this versatile tool. So next time you pick up a chainsaw for sale, remember the intricate workings that make it such a valuable asset in your arsenal of tools.

If you want to learn more, please visit our website.

The company is the world’s best ring saw for sale supplier. We are your one-stop shop for all needs. Our staff are highly-specialized and will help you find the product you need.

Featured content:The Versatility of FlashlightsWholesale chainsaw in China|Chain saw manufacturer&supplierWhat Are The Uses of Tricone Bit?The Difference Between Non-Sparking Tools And Anti-Static ToolsHow many teeth do I need on my saw blade?What type of paint roller gives the smoothest finish?The Intricate Art of Diamond Saw Blade Manufacturing

Comments

Please Join Us to post.

0