3. Wall

Wall formwork comes in different types and classifications, as outlined below.

Conventional

Conventional wall formwork consists of boards or sheets and squared timber. It is flexible, but it can be costly and time-consuming as each component must be assembled on-site. In addition, all of its parts should be made according to the project’s specifications, and they must be nailed together and dismantled again after concreting.

Girder

This is a better version of the conventional formwork. Its components, which usually consist of dimensionally stable girders with two chords and one web, have been standardized to facilitate the assembly of identical and ready-to-use panels. The connection of the panels has also been systematized.

Frame

This type of wall formwork helps reduce labor time since its essential components (forming face, support for forming face, and steel walers) are assembled as one panel. The profile nose of the frames protects the edges of the forming face, thereby extending its lifespan. Connecting devices are used when assembling the frame panels to large-sized units, which are then usually transported by crane.

Crane-independent (hand-set)

Featured content:Bottom-Line Benefits of Using Prepainted, Coil Coated Metal

Say goodbye to drywall cracks with Pe Joint Tape!The Benefits of Using 0.5 Mm Gi Sheet: Why It's Worth the InvestmentTop 5 Corrosion Prevention Tape Types to Extend LifespanADFORS® FibaFuse® 2-1/16" x 250' Fiberglass Mesh ...A Closer Look at the Various Types of Chicken Mesh for ...5 Inch Work?If you want to learn more, please visit our website Zolo.

This type of formwork can be moved by hand. Because of weight considerations, it is usually made of aluminum or plastic. It can take less concrete pressure than crane-dependent formwork, and is often used in housing and municipal construction projects.

Crane-dependent

Crane-dependent formwork systems feature a large frame and formwork panels, usually made of steel. As a result, they cannot be moved manually. Since they can resist more fresh concrete pressures than crane-independent forms, they are suitable for the construction of commercial buildings and other extensive infrastructure projects.

Two-sided

As the name implies, two-sided formwork is erected on both sides of the wall. Its formwork ties, which are usually sleeved by spacing plastic tubes so they can be reused, take up the fresh concrete pressure. Push-pull props or large heavy-duty braces are attached to the formwork to align and secure it against wind loads during operation.

Single-sided

Single-sided formwork is used when the concrete has to be poured against existing structures or when builders need to do concreting against a hill or soil. This is why it is most suitable for reconstruction jobs. With this type of formwork system, concrete pressure is transferred from the formwork to the base plates through a support structure.

Prefabricated

This formwork consists of two prefabricated concrete panels which are assembled in advance, and then transported and filled with concrete on-site. Braces and push-pull props are often used to secure the walls, while working and safety scaffolds are installed with the help of special adapters to make the construction process more cost-effective. Prefabricated formwork helps minimize project duration and labor costs. However, pre-planning is required to ensure that it is transported safely to the site.

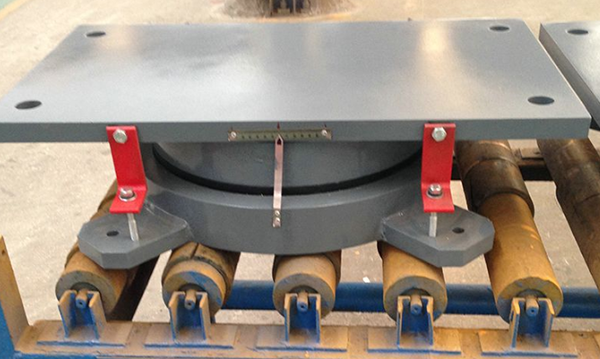

Circular

Circular formwork is designed for the construction of curved and polygonal walls. It is also quite useful in the construction of specific concrete structures, such as septic tanks and car park ramps. This formwork system comes in three different types:

- Round girder – timber spacers are added between the timber girders and steel walers so the formwork can be adjusted to the required radius.

- Flexible girder – ideal for the construction of curved walls with different radii. It comprises timber/steel girders and a spindle, which allows builders to adjust the formwork to the required radius without having to reassemble the panels.

- Polygonal – existing “flat” frame formwork panels can be refurbished as polygonal formwork by adding supplementary radius panels and rails, allowing builders to minimize their project costs.

Climbing

Climbing formwork is quite useful in the construction of high-rise concrete structures, such as control towers and skyscrapers, because it climbs with the wall. It comprises large wall formwork mounted to a climbing scaffold. There are three different types of climbing formwork:

- Crane-dependent – the climbing unit (scaffold and formwork) requires the use of a crane to reach the next cycle.

- Self-climbing – an automatic climbing system that does not require the use of a crane to reach the next suspension point. Hydraulic rams/pumps lift the scaffold, secondary platform, and formwork to the next pouring cycle. It is ideal for the construction of very tall concrete structures.

- Slipform – a two-sided formwork that slides upwards along the structure being built at a rate of 20–25cm per hour. A system of pipe rods, which is integrated into the already-set concrete, supports the slipform.

MEVA is an industry leader offering a wide variety of wall formwork systems that provide highly efficient shuttering, flexibility, and reliability. Our products are lightweight and easy to assemble, and therefore will facilitate the rapid completion of your construction projects. Click here to learn more.

If you want to learn more, please visit our website concrete slab formwork.

Comments

Please Join Us to post.

0